|

|

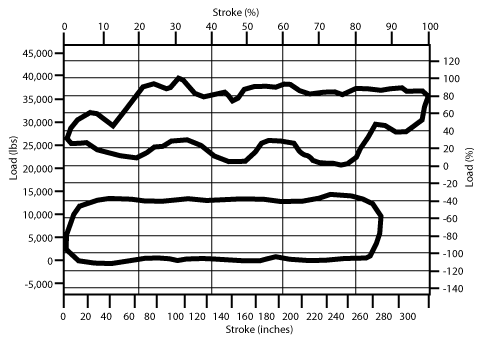

Our first case history

is a well with a Rotoflex 1100 pumping unit with a 306” stroke

length.

The 2’ bore pump is set at 8900 feet. The Cardbuild® System was installed In January of 2009. Prior to that time the

well was running approximately 3.5 SPM with a conventional VFD

system and was producing 380 BGPD. Prior history indicated about

3 failures per year that required a rig. These included tubing

leaks, rod parts and pump changes. Some of these issues

continued to be worked through after the Cardbuild®

System was installed. As existing problems were eliminated the

rig frequency decreased significantly. The last rig job was

3/29/2010. When the well was put back into operation after that

date, it ran approximately 5 SPM with a production test rate of

540 BGPD. It ran this way until January

2014 when it was replaced with a pumping unit with a 366” stroke

length. In the four years after the pre-existing problems were

cleared up, it required only routine maintenance work. It never

experienced a mechanical failure that required a rig or an

extensive shut down period. During this period, there were over

9,000,000 pump strokes and total fluid lifted was approximately

700,000 barrels.

Conclusion:

After

installation of the Cardbuild® System this well has consistently

operated at higher stroke speed which has increased well

displacement by approximately 40%. At the same time, equipment

failures, both surface and down hole, have dropped substantially.

|

Net results" |

|

|

| Conventional System |

CardBuild System |

|

|

|